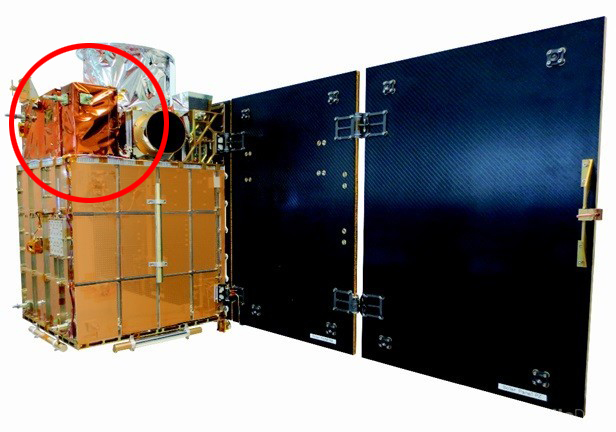

In a barren space environment, the satellite was required long-term missions with optimized conditions which block the extreme temperature deviations and emit internal heat properly. The satellite’s thermal control starts from this point of view. Heat pipes are used to take out the internal heat quickly and the Secondary Surface Mirrors (SSM) and Optical Solar Reflector (OSR) are installed to isolate and protect the payload from the harsh space environments.

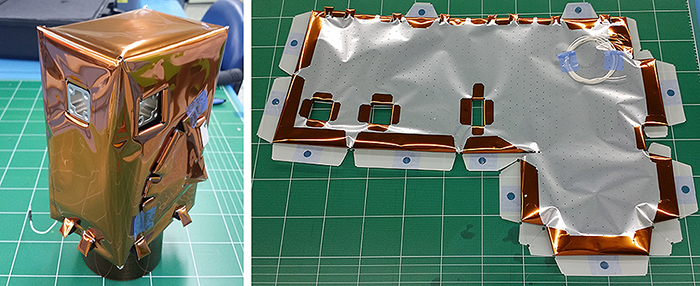

The satellite insulation uses the principle of blocking heat by radiant shielding from the space. It is called MLI (Multi-Layer Insulation) because it is made by repeatedly stacking reflective materials. MLI has very thin thickness and light weight.

Hinend’s job is to design, manufacture and install concerning for MLI. we analyze the assigned the condition, design the optimized shape for the satellite type and reduce the weight and volume of MLI.

The satellite division of Hinend has been built around Dr. Gyu-Hong Choi certified by ASTRIM. The satellite division has the entire capability for design, manufacturing and installation with the high- end class technicians.

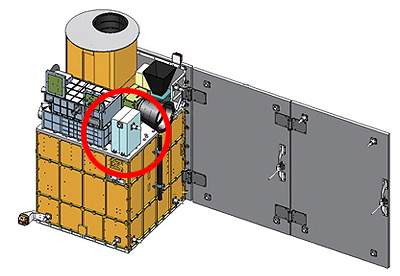

Design modeling image. Red circle OBC module

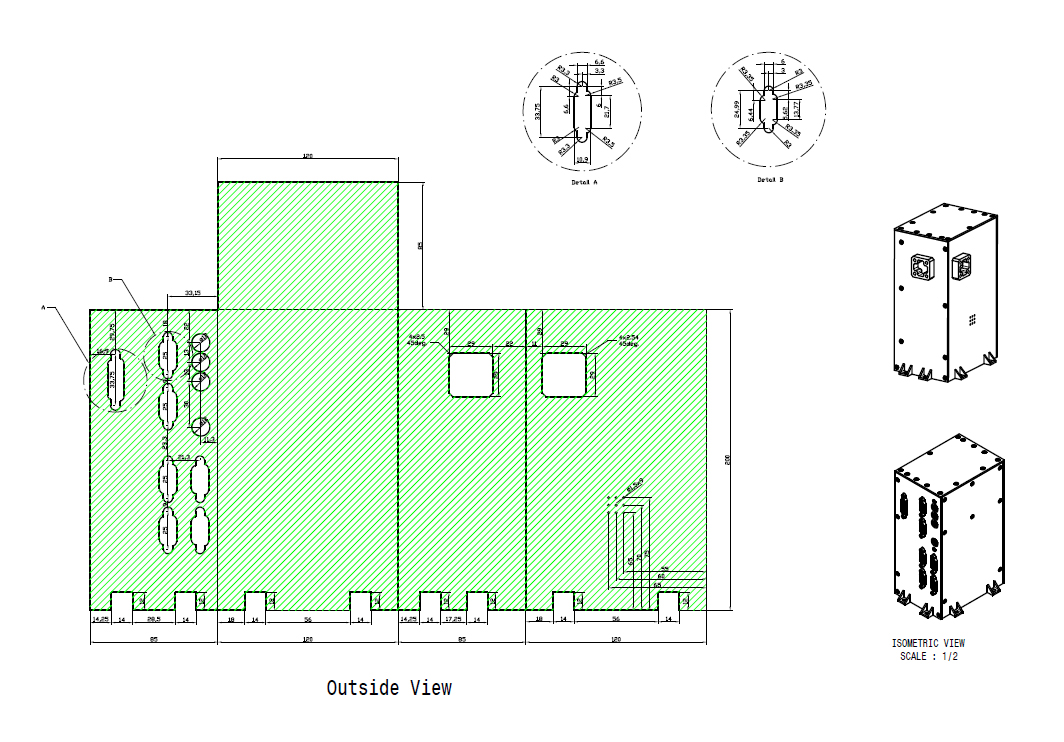

MLI drawings designed for OBC geometry

Certified engineers are participating as key engineers for satellite insulation design, fabrication and mounting missions.